| We Offer | |

|---|---|

| What is Helical Gear? Types, Benefits, and Applications | |

| Call Now | +91-958-682-3032 |

| +91-958-682-3032 | |

| Eligible Region | India |

| Category | Helical Gear |

| Payment Methods | Cash, UPI, Net Banking |

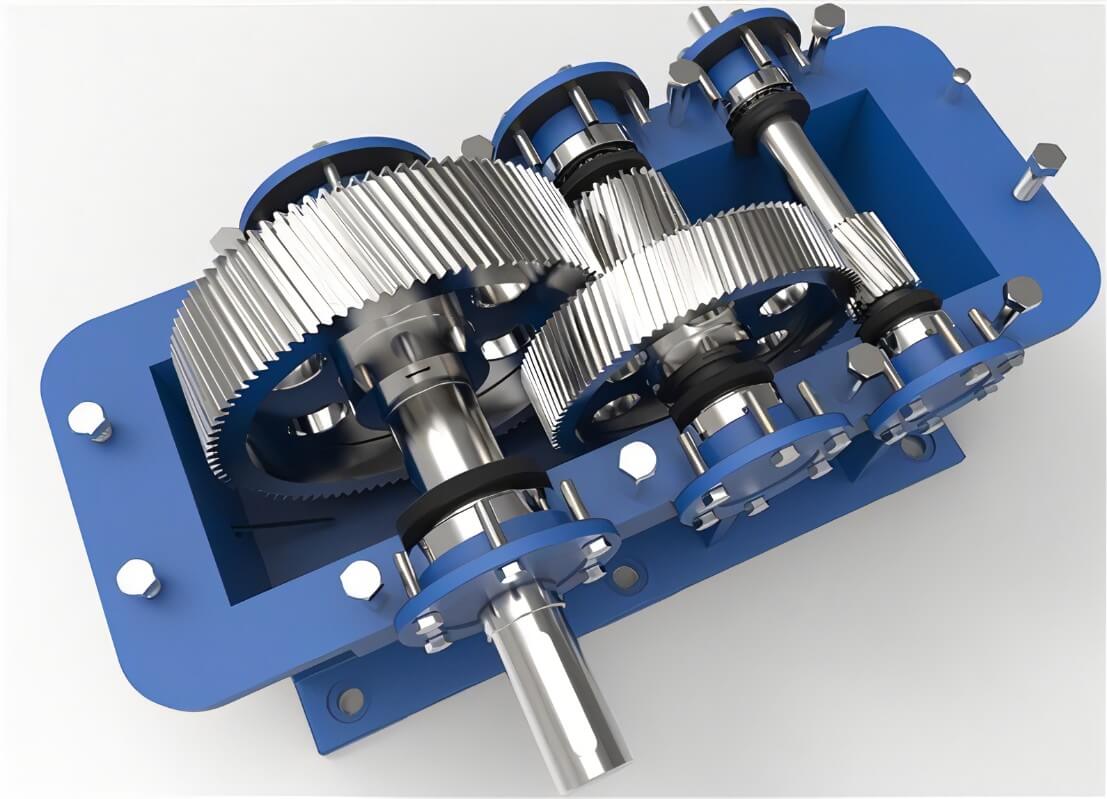

Helical gears are essential components in various mechanical systems, ensuring efficient power transmission between rotating shafts. Unlike other gear types, helical gears have angled teeth that engage gradually, resulting in smoother and quieter operation. That makes them excellent for operations requiring great torque and speed. Helical gears are used in industries such as automotive, industrial machinery, and robotics, thanks to their efficiency, durability, and performance. These gears are capable of handling heavy loads and providing precise control, making them a reliable choice in power transmission systems. We will explore the definition of helical gears and the different types, such as single helical and double helical gears, the benefits they offer, and their applications across various industries. Whether for reducing noise in automotive systems or enhancing the performance of industrial machinery, helical gears are integral to modern mechanical systems.

What is a Helical Gear?

A helical gear is a type of gear with teeth that are cut at an angle to the axis of rotation, forming a helical shape. This angled tooth design allows for a gradual engagement between the teeth, which results in smoother, quieter, and more efficient power transmission compared to straight-cut gears like spur gears. In helical gears, the teeth are not parallel to the axis but are set at an angle, typically between 15 and 45 degrees. This angled design enables the teeth to mesh gradually, as opposed to spur gears, which engage abruptly. As the teeth make contact, they create a rolling motion, reducing noise and vibration.

Comparison with Other Types of Gears

Spur Gears: These gears have straight teeth that are parallel to the axis of rotation. While spur gears are simple and cost-effective, they can generate more noise and vibrations when used in high-torque applications. Unlike helical gears, spur gears provide a direct engagement of teeth, which results in greater shock loading.

Bevel Gears: Bevel gears are utilized when the parallel axes of two shafts come together at an angle. These gears are ideal for changing the direction of power transmission, unlike helical gears, which are primarily used in parallel shaft systems.

How Helical Gears Differ in Design and Function

The key difference between helical gears and other gears is the tooth design. The teeth of helical gears are angled, which allows them to engage more gradually and provide smoother power transmission. This design results in less vibration, lower noise levels, and higher load-carrying capacity. Helical gears are often used in high-speed, high-load applications where smooth operation is crucial.

Types of Helical Gears

There are several types of helical gears, each offering specific advantages depending on the application.

Single Helical Gears

Single helical gears feature a set of teeth cut at an angle on only one side of the gear. These gears are commonly used in mechanical systems that require moderate load capacities and smooth operation.

Key Features

Single helical gears have been designed for minimalism and cost-effectiveness. They provide smoother engagement compared to spur gears and are generally used when space is a constraint. These gears are highly efficient, transferring power with minimal energy loss.

Benefits and Limitations

Benefits:

- Smooth and quiet operation

- Higher load-carrying capacity than spur gears

- Reduced shock loads and vibrations

Limitations:

- Can create axial thrust, which may require additional support or bearings

- Less efficient in some high-torque, high-speed applications compared to other gear types

Double Helical Gears

Double helical gears feature teeth cut on both sides of the gear, arranged in a V-shape. This design eliminates the axial thrust seen in single helical gears and provides a more balanced load distribution.

Explanation of the Design and Benefits

The double helical gear has two sets of teeth, angled in opposite directions. This structure helps to cancel off axial thrust, making operation smoother. Double helical gears are often used in heavy-duty applications where high torque and load-carrying capacity are needed.

Applications Where Double Helical Gears Are Most Commonly Used

- Heavy machinery: Used in large industrial machines where high loads and torque are involved

- Marine applications: Ideal for ships and marine systems where high reliability and smooth operation are needed

- Automotive systems: Used in some gearboxes and differential systems for better load distribution and reduced wear

Benefits of Helical Gears

Helical gears offer numerous advantages that make them a preferred choice for many industrial applications.

Smooth and Quiet Operation

One of the most significant benefits of helical gears is their ability to operate quietly. The meticulous interaction of the teeth decreases the usual noise and vibrations associated with gears. This makes helical gears ideal for applications where noise reduction is critical.

Higher Load-Carrying Capacity

Helical gears provide a higher load capacity than spur gears. The angled teeth engage gradually, allowing them to support heavier loads without causing excessive wear or failure. This makes helical gears ideal for high-torque applications.

Improved Meshing Action and Efficiency

The gradual tooth engagement in helical gears results in smoother meshing, reducing friction and energy loss. This leads to more efficient power transmission, improving the overall performance of the machinery.

Less Prone to Wear and Tear

Due to the gradual contact between teeth, helical gears experience less stress and wear than spur gears. This helps increase their lifespan and reduces the frequency of maintenance.

Better Transmission Accuracy

The design of helical gears enables them to provide better precision in power transmission, resulting in smoother motion and more accurate control over machinery. This is crucial in applications that require high accuracy.

Applications of Helical Gears

Helical gears are widely used in various industries due to their efficiency and reliability.

Automotive Industry

In the automotive industry, helical gears are used in gearboxes, differentials, and transmission systems. Their smooth and quiet operation makes them ideal for vehicles where comfort and performance are a priority.

Industrial Machinery

Helical gears are commonly found in industrial machinery, including pumps, compressors, and conveyor systems. They are used to transmit high torque and ensure the smooth functioning of heavy-duty equipment.

Marine Applications

In marine applications, helical gears are used in ship propulsion systems and other marine equipment. Their ability to withstand high loads and provide smooth operation makes them essential in the maritime industry.

Power Transmission Systems

Helical gears are used in power transmission systems where efficient and reliable power distribution is crucial. Their ability to handle high torque and provide smooth power transfer makes them ideal for these applications.

Robotics and Automation

In robotics and automation, helical gears are used in actuators, servo motors, and other robotic systems. Their precision and smooth operation ensure the accurate and reliable movement of robotic parts.

Who is the Leading Manufacturer of Helical Gear?

Muratech Engineering Company is a leading Helical Gear manufacturer in India, renowned for producing high-quality gears that meet the demands of various industries. With years of expertise, we built a strong reputation for delivering durable and reliable helical gears. These gears are designed for efficient power transmission, offering smooth, quiet, and precise performance. From automotive applications to industrial machinery, we provide customized helical gears tailored to meet specific customer requirements. Our dedication to quality, along with innovative production procedures, ensures that every helical gear meets the highest requirements. Muratech Engineering Company is the No. 1 company for manufacturing and exporting of helical gears in India and throughout the world, known for their durability and affordability. Contact Muratech Engineering Company today for the best helical gear solutions, engineered for optimal performance and longevity.

Conclusion

Helical gears are essential components in a wide range of mechanical systems, offering efficiency, durability, and precision. Whether in automotive systems, industrial machinery, or power transmission, their smooth operation and high load-carrying capacity make them a preferred choice. With various types, such as single helical gears and double helical gears, businesses can select the right gear for their specific needs. As technology advances, helical gears will continue to play a pivotal role in improving the performance and reliability of mechanical systems.

For high-quality helical gears and expert guidance, contact Muratech Engineering Company today at +91-958-682-3032 or email muracopower@hotmail.com