Leading manufacturer & Exporter in Ahmedabad, India

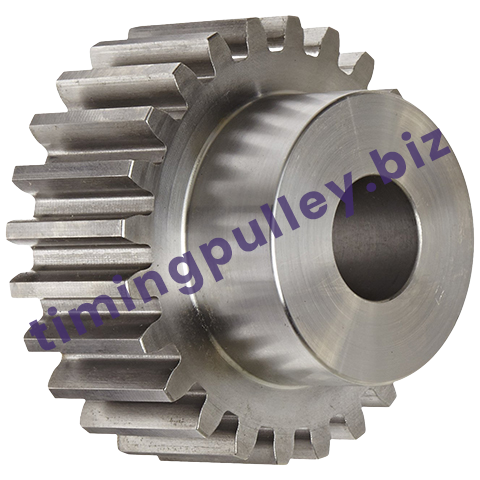

Spur Gear Manufacturer

Muratech Engineering Company is a renowned spur gear manufacturer, recognized globally for delivering top-quality gear products. Since our establishment in 1990, we have been a trusted industrial spur gear manufacturer, supplier, and exporter, certified under ISO 9001:2015 and ISO 45001:2018 standards. Our company is located in Ahmedabad, Gujarat, India, and offers a wide range of spur gears at competitive prices to meet diverse industrial needs. Spur gears are the most commonly used gear type, known for their simplicity and efficiency in power transmission.

These gears feature teeth cut parallel to the gear axis and mounted on a cylindrical body. Muratech spur gears are designed using the involute tooth profile, a design widely recognized for its smooth and reliable operation. The involute shape ensures a constant velocity ratio and minimal interference, making it perfect for various industrial applications.

While the involute form remains the industry standard, cycloidal teeth may be used in precision instruments like clocks for smoother motion. For heavy-duty applications, our gears are designed with different pressure angles, 20°, and 25° being the most popular for optimal load-bearing capacity and durability. In select cases, we are also the manufacturer of high-pressure angle gears (up to 45°) for specialized use. Muratech Engineering Company, a leading industrial spur gear manufacturer in India, uses advanced technology, technical experience, and high standards of quality to provide long-lasting and cost-effective gear solutions all over the world.

India’s Leading Spur Gear Manufacturer

Muratech Engineering Company is India’s leading Spur Gear Manufacturer company in India, known for offering reliable and high-performance gear solutions. We have established an excellent reputation as an Industrial Spur Gear Manufacturer by providing high-quality products that meet industry requirements. We specialize in manufacturing a complete range of spur gear in India, available for diverse industrial applications. As a leading spur gear manufacturer, we provide totally customizable spur gears in a wide range of shapes, sizes, and specifications. Each spur gear is manufactured with precision using top-grade raw materials and modern machinery. Our spur gears are known for their superior strength, long operational life, and accurate dimensions, making them ideal for demanding industrial environments.

As a well-known spur gear manufacturer in India, we are committed to serving every customer's specific demands. Our expert team provides every gear made with attention to detail, providing smooth performance and minimal maintenance. These cylindrical gears with straight teeth are widely used to transfer motion, power, and torque between parallel shafts. Choose Muratech Engineering Company as your reliable Industrial Spur Gear Manufacturer for the best quality spur gear in India at competitive prices.

Materials Used for Spur Gear

- Carbon Steel

- EN Material (EN8, EN9, EN19, EN31, EN353)

- Alloy Steel

- CR Material (20MNCR5)

- Bronze

- Delrin Plastic & Cast Nylon

- Stainless Steel

- Phosphor Bronze

- Cast Iron, etc.

Types of Spur Gear

- External Spur Gear

- Internal Spur Gear

- Helical Spur Gear

- Double Helical Spur Gear

- Pinion Gear

Benefits of Spur Gear

- High Efficiency: Spur gears offer excellent power transmission efficiency due to minimal tooth friction. Their simple connecting allows maximum energy transmission, making them perfect for high-performance systems with dependable and constant mechanical output.

- Simple Design: With a basic structure and parallel teeth, spur gears are easy to manufacture and maintain. Their simplicity results in lower production costs, minimal maintenance requirements, and quick integration into various industrial machines and equipment.

- Durability: Spur gears are made from strong, wear-resistant materials that handle significant load and torque. Their sturdy build provides long-lasting performance, even in demanding environments, making them a dependable choice for continuous industrial operations.

- Variety: Available in multiple sizes, materials, and configurations, spur gears can suit diverse applications. Their adaptability, cost-effectiveness, and easily installation make them suitable for everything from light-duty tasks to heavy industrial machinery requirements.

Strong and efficient Spur Gear production capabilities

| Factors | Parameters |

|---|---|

| Diameter Up to | 15” |

| Diametrical Pitch Up to | 50.8 to 2.54 |

| Module Up to | 0.5 to 10 |

| Face Width | 15” |

| Production Volume | Prototype, Small to Large Run |

| Material Formation of Gear | Turning or machining the Solid Round Bar |

| Material Uses | Polycarbonate (Acetal/Delrin), Alloy Steel, Carbon Steel, Brass, Cast Iron, EN Material (EN8, EN9, EN19, EN31, EN353), CR Material (20MNCR5) |

| Gear Cutting Technique | Hobbing, Shaping, Milling, Grinding, EDM, Case Hardening, Black Oxide, Zinc & Chrome Plating, Wire Cut |

| Potential Shaft Feature | Flat or Hexagonal |

| Heat Treatment Process | Carburizing or Nitrating as per required HRC |

| Final Finishing | Grinding or Lapping |

| Application Industries | Automotive, Pharmaceuticals, Packaging, Paper, Machinery, Construction, Marine, Chemicals, Food Processing |

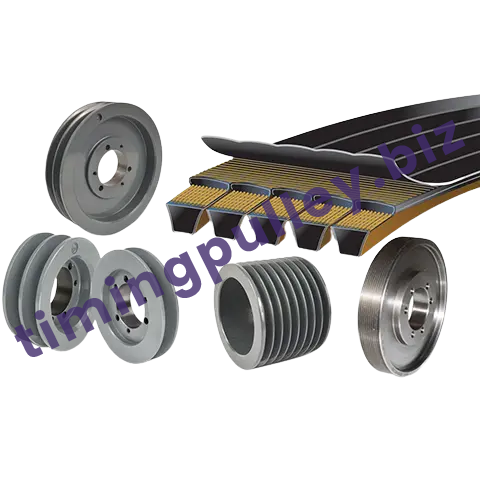

OUR COMPLETE RANGE OF POWER TRANSMISSION PRODUCTS

TIMING BELT PULLEY

We are manufacturer of all types of timing pulley T2.5, T5, T10, T20, 3M HTD, 5M HTD, 8M HTD, 14M HTD, 20M HTD, 40DP-2.07, MXL-2.032, XL-5.08, L-9.525, H-12.7, XH-22.225, XXH-31.75, AT5, AT10, AT20, GT5, GT10, S 3M, S 5M, S 8M, S 14M, S 20M.

Industries We Serve

Muratech Engineering Timing Pulleys are used in industries like as:

- Oil Mill

- Sugar Mill

- Textile Mill

- Crusher Plant

- Dairy Plant

- Gining Mill

- Rolling Mill

- Rice Mill

- Paper Mill

- Food Machinery

- Gases Industries

- Power Plant

- Pump & Compressor

- Printing Industry

- Packaging Industry

- Pharma Industry

- Textile Machinery