Leading manufacturer & Exporter in Ahmedabad, India

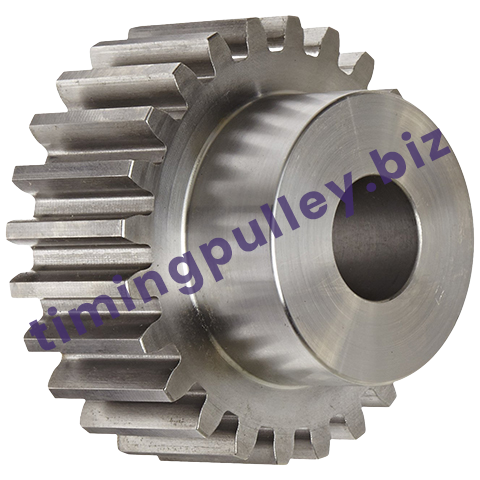

Helical Gear Manufacturer

Muratech Engineering Company is one of the world’s top helical gear manufacturers, suppliers, and exporters, established in 1990. The company, based in Ahmedabad, Gujarat, India, is ISO 9001:2015 and ISO 45001:2018 certified. We are known for providing high-quality industrial helical gear at highly competitive prices across domestic and international markets. A helical gear features teeth set at an angle to the gear axis, creating a spiral-shaped pattern that allows for smoother and quieter operation compared to straight-cut gears.

This gear type can efficiently transfer motion between parallel as well as non-parallel shafts, making it a versatile choice for various applications. When utilized in nonparallel designs, the gears are commonly known as spiral gears. Helical gears operate more smoothly and quietly than spur gears because their angled teeth contact gradually. Because of their design, Helical Gears offer better load distribution and are capable of carrying higher loads. They also reduce vibration and noise, improving machinery life and efficiency. When compared to spur gears, smaller-sized Helical Gears can often handle the same level of torque and force.

External parallel shaft usage feature Helical Gears with similar helix angles but opposing hand arrangements. Load capacity improves as the helix angle increases, usually up to 45°, but noise reduces. However, above 15° - 20°, tooth thickness starts to decrease. In these circumstances, Herringbone or Double Helical Gears are used for silent operation without making axial thrust. Muratech helical gears are either manufactured as one continuous form or assembled as two matched components, with a small groove at the center for manufacturing ease. This configuration balances thrust loads, making them ideal for parallel shaft use. Muratech Engineering Company is a manufacturer of Helical Gears to meet varied industrial requirements using advanced machines and high-grade materials. As a renowned Helical Gear Manufacturer in India, we provide performance-oriented products that are designed to finalize. We are committed to offering excellence in gear engineering.

India’s Leading Helical Gear Manufacturer

Muratech Engineering Company is widely regarded as one of India’s leading Helical Gear Manufacturer company. We are known for delivering precisely engineered gears that meet global standards. These gears have teeth cut at an angle (helix), which gives better transmission and better strength. For parallel shaft setups, one gear is right-handed while the other is left-handed. For non-parallel shafts like right-angle arrangements, both gears are either right-handed or left-handed. This flexibility allows Helical Gears to be used across a wide range of mechanical systems.

Muratech Engineering Company, an Industrial Helical Gear Manufacturer, uses only premium materials and innovative technology to make gears that can experience heavy weights and long-term work. Our company offers a wide variety of industrial helical gears in multiple sizes, finishes, and technical specifications based on customer needs. The gears are known for their ability to handle tough industrial environments, providing reliable transmission and long service life. Our commitment to outstanding customer service and quality has established us as a leading helical gear manufacturer. Whether it’s for automotive, conveyor, or heavy-duty machinery applications, we deliver world-class Helical Gear in India that meets every demand with consistency and excellence.

Types of Helical Gears

- Single Helical Gears

- Double Helical Gears (Herringbone Gears)

- Spiral Bevel Gears

- Hypoid Gears

Materials Used for Helical Gear

- PolyCarbonate

- Alloy Steel

- Carbon Steel

- Brass

- Delrin Plastic & Cast Nylon, etc.

Features of Helical Gears

- Angled Teeth Design: Helical gears feature teeth cut at an angle to the gear axis, making an angled helix. This design allows multiple teeth to engage simultaneously, providing smooth and continuous power transmission.

- Smooth and Quiet Operation: Helical gears are less noisy and vibration-prone than spur gears, which makes them perfect for high-speed and heavy-duty uses.

- High Efficiency with Thrust Load: Muratech Helical gears offer efficient power transfer but generate axial thrust due to the angled teeth. This thrust can be managed using proper shaft support and bearings.

- Robust Materials: Muratech Helical gears are commonly manufactured using materials like alloy steel, stainless steel, brass, or cast iron, depending on the application’s strength and durability needs.

- Customizable Helix Angle: The helix angle can be adjusted to suit specific performance needs higher angles improve load-carrying capacity, while lower angles enhance smoothness and reduce friction.

Benefits of Helical Gears

- Provides more comfortable and quieter performance than spur gears

- Increased load-carrying capability, perfect for heavy-duty applications

- Generates reduced axial thrust, improving gear alignment

- Designed for use with both parallel and nonparallel in shaft setups

- Provides high gear ratios with better power transmission efficiency

- Highly designed for automobile systems to make sure efficient operation

Strong and efficient Helical Gear production capabilities

| Factors | Parameters |

|---|---|

| Diameter Up to | 15” |

| Diametrical Pitch Up to | 50.8 to 2.54 |

| Module Up to | 0.5 to 10 |

| Face Width | 15” |

| Production Volume | Prototype, Small to Large Run |

| Material Formation of Gear | Turning or machining the Solid Round Bar |

| Material uses | Materials used including polycarbonate (acetal/delrin), alloy steel, brass, carbon steel, and cast iron |

| Gear Cutting Technique | Hobbing, Shaping, Milling, Grinding, Shaping, EDM, Case Hardening, Black Oxide, Zinc & Chrome Plating, Wire Cut |

| Potential Shaft Feature | Flat or Hexagonal |

| Heat Treatment Process | Carburizing or Nitrating as per required HRC |

| Final Finishing | Grinding or Lapping |

| Application Industries | Automotive, Pharmaceuticals, Packaging, Paper, Machinery, Construction, Marine, Chemicals, Food Processing |

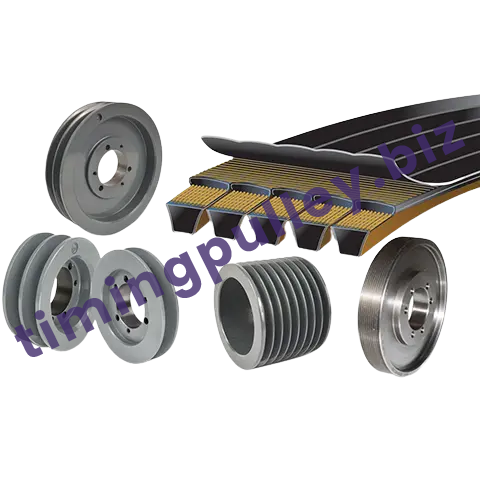

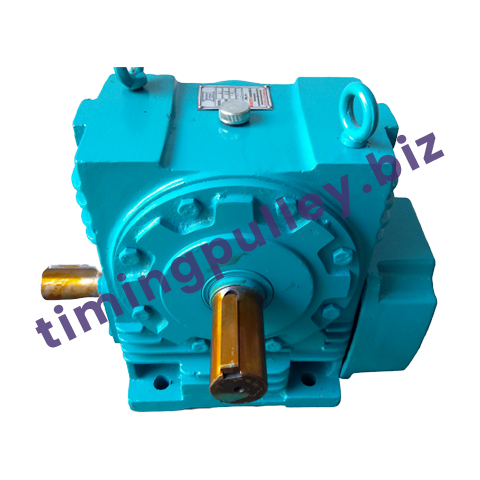

OUR COMPLETE RANGE OF POWER TRANSMISSION PRODUCTS

TIMING BELT PULLEY

We are manufacturer of all types of timing pulley T2.5, T5, T10, T20, 3M HTD, 5M HTD, 8M HTD, 14M HTD, 20M HTD, 40DP-2.07, MXL-2.032, XL-5.08, L-9.525, H-12.7, XH-22.225, XXH-31.75, AT5, AT10, AT20, GT5, GT10, S 3M, S 5M, S 8M, S 14M, S 20M.

Industries We Serve

Muratech Engineering Timing Pulleys are used in industries like as:

- Oil Mill

- Sugar Mill

- Textile Mill

- Crusher Plant

- Dairy Plant

- Gining Mill

- Rolling Mill

- Rice Mill

- Paper Mill

- Food Machinery

- Gases Industries

- Power Plant

- Pump & Compressor

- Printing Industry

- Packaging Industry

- Pharma Industry

- Textile Machinery