Leading Manufacturer & Exporter in Ahmedabad, India

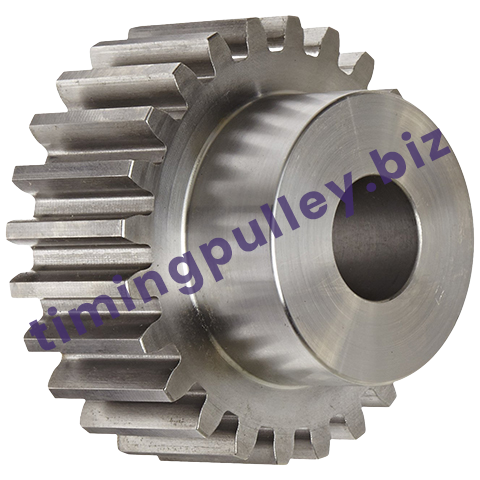

Bevel Gears / Spiral Bevel Gears Manufacturers

Muratech Engineering Company is a top bevel gears and spiral bevel gears manufacturer, supplier, and exporter, established in 1990. We are an ISO 9001:2015 and ISO 45001:2018 certified company with its head office in Ahmedabad, Gujarat, India. As a renowned industrial bevel gear manufacturer, we are known for offering premium-quality gears at competitive prices across India and the global market. Bevel gears distribute power within shafts that meet at an angle of 90°. Muratech Engineering Company is a manufacturer of a wide range of bevel gears and spiral bevel gears in India, suitable for various industrial applications.

These gears are classified as straight bevel gears or spiral bevel gears depending on the shape and orientation of their teeth. Spiral bevel gears, with curved teeth, ensure smoother, quieter, and more efficient operation, making them ideal for high-speed and heavy-duty applications.

As a top Bevel Gears and Spiral Bevel Gears manufacturer company, we provide gears made from premium materials such as S45C machine structural carbon steel, SCM415 alloy steel, MC901 engineering Plastics and various other specialty materials are used to improve both performance and strength. Our gears are also available in polished or unpolished finishes based on the application needs. We provide superior quality, long-lasting performance, and complete customer satisfaction in every product we deliver. We continuously upgrade our production facilities with modern technology to meet the growing demand for Bevel Gears and Spiral Bevel Gears in India and across the world.

India’s Leading Bevel Gears/Spiral Bevel Gears Manufacturer

Muratech Engineering Company is widely regarded as one of India’s leading bevel and spiral bevel gear manufacturers. we specialize in producing high-quality bevel gears and spiral bevel gears for diverse industrial applications. These gears are designed to transmit motion between two intersecting shafts based on rolling contact between two cones, known as pitch cones. The pitch cone angle, defined by the intersection of these cones, plays a crucial role in accurate bevel gear design. As the largest manufacturer of bevel gears and spiral bevel gears, we provide both straight and spiral bevels. When the pitch angle of a gear reaches 90°, it forms a crown gear, commonly used as a base reference for tooth cutting in bevel gear systems. Conical and face gears are also part of the spiral bevel gear group, used in specialized applications across multiple industries.

Our bevel gears and spiral bevel gears in India are known for their durability, smooth operation, and efficiency. Spiral bevel gears offer a higher tooth contact ratio, reducing noise and vibration, making them perfect for high-speed, heavy-load operations. Muratech Engineering Company offers reliable manufacturing and superior gear grinding after heat treatment, making sure long-lasting reliable operation in all of our bevel gear solutions.

Types of Bevel Gears/Spiral Bevel Gears

Muratech Engineering Company is a manufacturer of both Straight Bevel Gears and Spiral Bevel Gears as per industry standards or customized to meet specific customer requirements.

- Straight bevel gear

- Spiral bevel gear

Materials Used for Bevel Gears/Spiral Bevel Gears

- Alloy Steel (e.g., SCM415)

- Carbon Steel (e.g., S45C)

- Cast Iron

- Stainless Steel

- Phosphor Bronze

- Nylon/Engineering Plastics (e.g., MC901)

- Duracon (POM)

Features of Bevel Gears/Spiral Bevel Gears

- Transmit motion between intersecting shafts

- Available in straight and spiral tooth designs

- Spiral teeth offer smoother and quieter operation

- High load capacity with precise torque transfer

- Ideal for high-speed and heavy-duty applications

- Customizable in size, material, and configuration

Benefits of Bevel Gears/Spiral Bevel Gears

- Compact Design

- Power Transmission at Intersecting Angles

- High Load Capacity

- Smooth and Quiet Operation (Spiral Bevels)

- Versatility

- Precise Motion Control

- Durable Construction

- Reduced Noise and Vibration

- Cost-Effective

- Ability to Change Operating Angle

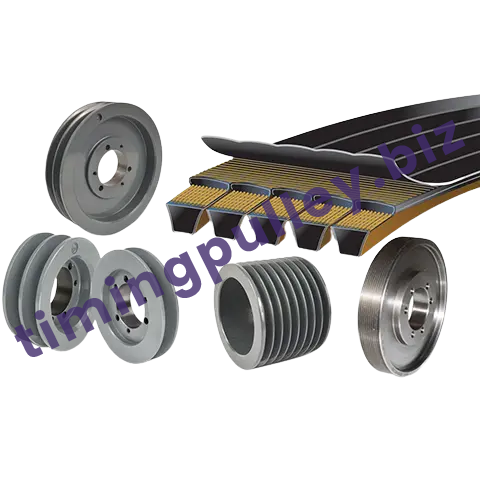

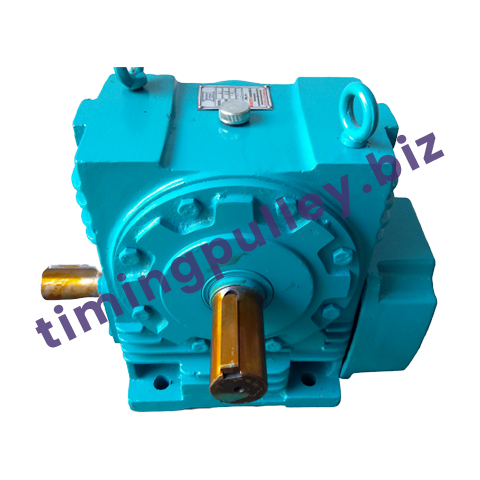

OUR COMPLETE RANGE OF POWER TRANSMISSION PRODUCTS

TIMING BELT PULLEY

We are manufacturer of all types of timing pulley T2.5, T5, T10, T20, 3M HTD, 5M HTD, 8M HTD, 14M HTD, 20M HTD, 40DP-2.07, MXL-2.032, XL-5.08, L-9.525, H-12.7, XH-22.225, XXH-31.75, AT5, AT10, AT20, GT5, GT10, S 3M, S 5M, S 8M, S 14M, S 20M.

Industries We Serve

Muratech Engineering Timing Pulleys are used in industries like as:

- Oil Mill

- Sugar Mill

- Textile Mill

- Crusher Plant

- Dairy Plant

- Gining Mill

- Rolling Mill

- Rice Mill

- Paper Mill

- Food Machinery

- Gases Industries

- Power Plant

- Pump & Compressor

- Printing Industry

- Packaging Industry

- Pharma Industry

- Textile Machinery