| We Offer | |

|---|---|

| What is a QD Bush Pulley? How to Install and Remove QD Bushings | |

| Call Now | +91-958-682-3032 |

| +91-958-682-3032 | |

| Eligible Region | India |

| Category | QD Bush Pulley |

| Payment Methods | Cash, UPI, Net Banking |

Smooth functioning is important for efficiency in mechanical systems, and the QD Bush Pulley contributes significantly to this. Commonly used in power transmission systems, the QD Bush Pulley connects the pulley to the shaft securely. It allows for easy installation and removal, offering convenience during maintenance and repairs. This versatile component enhances the overall performance of machinery by transmitting rotational force efficiently. Here we will explore the QD Bush Pulley in detail, discussing its importance in various mechanical systems, as well as step-by-step instructions for installing and removing QD bushings. Additionally, we'll highlight the leading manufacturers of QD Bush Pulleys, known for providing high-quality, durable solutions. Understanding how to properly install and remove QD bushings can ensure the longevity and efficiency of your mechanical systems, making it an essential aspect of maintenance.

What is a QD Bush Pulley?

A QD (Quick Detach) Bush Pulley is a mechanical device used to transmit power in various systems. The QD bush pulley is designed to quickly and securely mount onto a shaft without the need for special tools or procedures, which makes it ideal for systems requiring regular maintenance or adjustments. The pulley is typically connected to a shaft via a QD bushing, which is a sleeve-like device that fits onto the shaft, allowing the pulley to be mounted securely while providing easy detachment when necessary.

Functionality of QD Bush Pulleys

The primary function of a QD bush pulley is to transmit rotational force from one component to another, such as from a motor to a machine part like a fan or conveyor belt. This process helps in converting the energy produced by the motor into useful work, moving materials or machinery as required. By securely connecting the pulley to the shaft with a QD bushing, the system minimizes slippage and ensures smooth power transfer.

Advantages of Using QD Bush Pulleys

- Easy Installation and Removal: One of the main benefits of QD bush pulleys is the ease with which they can be installed and removed. The Quick Detach system allows the pulley to be mounted or removed without much effort, saving time during installation or maintenance.

- Flexibility: QD bush pulleys are adjustable and may be utilized in a variety of applications, including small machines and as big industrial systems.

- Enhanced Durability: The robust design of QD bush pulleys ensures long-lasting performance, reducing the need for frequent replacements.

- Minimized Downtime: The quick installation and removal process reduce downtime, which is crucial in maintaining continuous operations in industries.

Types of QD Bush Pulleys

Several types of QD bush pulleys are available in the market, each catering to specific mechanical applications:

- Standard QD Bush Pulley: Designed for general power transmission applications, these pulleys are ideal for most machinery.

- Heavy-Duty QD Bush Pulley: Used in more demanding industrial environments, these pulleys are built to handle higher loads and torque.

- V-Belt QD Pulley: These pulleys are designed to work with V-belts, making them ideal for applications involving belt-driven systems.

How to Install a QD Bushing

Installing a QD bushing is a straightforward process, but it must be done correctly to ensure proper functioning. Follow these procedures to properly install a QD bushing.

Step-by-Step Installation Process

- Prepare the Shaft: Ensure the shaft is clean and free of debris. If the shaft is dirty, it can prevent the bushing from fitting correctly and cause damage over time.

- Insert the Bushing into the Pulley: Place the QD bushing into the center of the pulley. Check that the bushing fits properly with the holes on the pulley and shaft.

- Slide the Bushing onto the Shaft: Carefully pass through the pulley into the shaft, with the bushing in its place. Ensure the bushing aligns perfectly with the shaft's keyway.

- Tighten the Bolts: Secure the pulley in place by tightening the bolts on the bushing. These bolts will draw the bushing tighter onto the shaft, ensuring a secure fit.

- Check Alignment: Once the bushing is in place, double-check that the pulley is properly aligned. A misaligned pulley can cause the system to work inefficiently or lead to premature wear.

Tools and Materials Needed

- QD Bushing: Ensure the correct size for your pulley and shaft.

- Wrenches: For tightening bolts.

- Lubricant: To lubricate the shaft and bushing for easy installation.

- Measuring Tools: To verify proper alignment of the pulley.

Tips for Assuring Proper Installation and Alignment

- Always use the manufacturer-recommended bushing size for your pulley and shaft to ensure compatibility.

- Avoid over tightening the bolts, as this can damage the bushing or shaft.

- Regularly check the alignment of the pulley and bushing to avoid unnecessary wear and tear.

How to Remove a QD Bushing

Removing a QD bushing is a simple process, but care must be taken to avoid damaging the shaft or pulley during the procedure. Here's a step-by-step guide on how to remove a QD bushing safely:

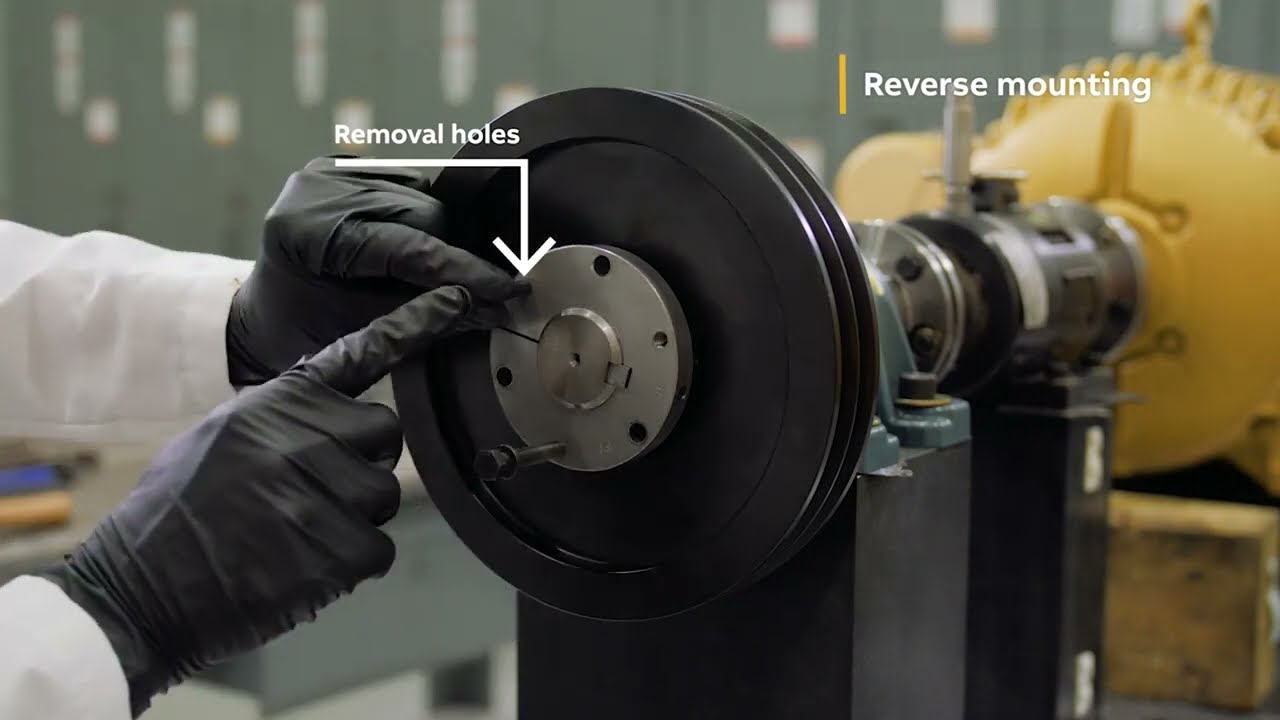

Step-by-Step Removal Process

- Loosen the Bolts: Begin by loosening the bolts securing the bushing to the pulley. These bolts should be turned counterclockwise.

- Use a Puller Tool: If the bushing is stuck, use a bushing puller tool. Attach the tool to the bushing and slowly pull it out from the pulley. Ensure the puller tool is correctly aligned to avoid damaging the bushing or the pulley.

- Remove the Bushing: Once the bushing is loose, carefully slide it off the shaft. If the bushing is difficult to remove, gently tap the side of the bushing with a soft hammer to break any corrosion or friction.

- Inspect Components: After removing the bushing, inspect both the shaft and the bushing for damage or wear. If any parts appear worn, they should be replaced before reinstallation.

Tools and Techniques for Removing a Stubborn Bushing

- Bushing Puller Tool: This tool is essential for removing stubborn bushings without damaging the shaft.

- Lubricant: Apply lubricant to the shaft before removal to help loosen the bushing.

- Soft Hammer: Gently tap the bushing to loosen it if necessary.

Common Problems and Troubleshooting Tips

- Stuck Bushing: If the bushing is stuck, make sure to use the correct puller tool. Excessive force might harm the components, therefore avoid using it.

- Corrosion: If corrosion is present on the shaft or bushing, it may require additional lubrication or tapping with a hammer to break the bond.

- Damaged Shaft: Inspect the shaft for any signs of wear or damage before installing a new bushing.

Who is the Leading Manufacturer of QD Bush Pulleys?

When selecting a QD bush pulley, it's important to choose a trusted manufacturer known for quality and reliability. Muratech Engineering Company, established in 1990, is a leading QD bush pulley manufacturer in India. Renowned for producing high-performance and durable QD bush pulleys, Muratech has earned a solid reputation across various industries. The company ensures that all its products, including spur gears, helical gears, timing pulleys, bevel gears, poly V pulleys, and worm reduction gearboxes, meet the highest standards of quality. Muratech Engineering Company provides the best solutions for a wide range of mechanical applications, ensuring that each QD bush pulley delivers optimal performance. Their focus on quality makes them the ideal choice for businesses seeking reliable and efficient components to enhance their mechanical systems.

Conclusion

Understanding how a QD bush pulley works, as well as how to properly install and remove it, is crucial for maintaining efficiency and reducing downtime in mechanical systems. These pulleys provide a simple, effective, and flexible solution for power transmission across various applications. Whether you are replacing a worn-out part or installing a new system, knowing the proper installation and removal techniques ensures smooth operation and longevity of your equipment.

For more information or to purchase QD bush pulleys, Muratech Engineering Company is a trusted name offering high-quality, durable solutions. To inquire about our products or get expert advice, contact us at +91-958-682-3032 or email us at muracopower@hotmail.com.